-

Posted: June 23, 2017|Read more »

Here is a quick list of common damages that V belts suffer and the causes. Always use your replaced belts as an important source to find problems on your machinery and correct them once you replace your belt.

1. Rapid Sidewall Wear caused by: Belts Rubbing Guard, Worn or Damaged Sheaves, Sheaves Misaligned, Insufficient Tension, Wrong Belt Cross-Section or Type, Improper or Prolonged Storage, Excessive Heat, Excessive Oil or Grease, Use of Belt Dressing, Abrasive Environment, Excessive Moisture, Inappropriate Sheave Material, Improper Tensioned Idler

2. Worn Cover on Back caused by: Defective or Worn Backside Idler, Belts Pried On or Misplaced Slack

3. Belt Soft, Swollen caused by: Use of Belt Dressing, Excessive Exposure to Oil or Grease

4. Belt Slips, Squeals (Spin Burn) caused by: Worn or Damaged Sheaves, Insufficient Tension, Wrong Belt Cross-Section or Type, Excessive Oil or Grease, Excessive Moisture, Overload Drive-Under belting, Insufficient Wrap on Small Sheave

5. Belt Cover Split cause by: Belts Pried On or Misplaced Slack, Foreign Objects In Grooves

6. Underside Cracked caused by: Excessive Heat, Sheaves Too Small, Undersized Backside Idler, Improperly Positioned Backside Idler, Sheaves Misaligned, Improper Or Prolonged Storage

7. Missing Cogs caused by: Excessive Heat, Sheaves Too Small, Backside Idler, Sheaves Misaligned, Improper or Prolonged Storage

8. Cracked Bushings caused by: Excessive Tension, Worn or Damaged Sheaves, Prying open The Split With a Screwdriver

-

Posted: June 23, 2017|Read more »

Bhagyoday Belt Company from the day of inception, we have been single mindedly driven by the vision of achieving highest level of customer satisfaction by providing quality products and thereby, emerging as a strong Player by setting high standards in quality, prompt delivery schedules and after sales service.

Based in Ahmedabad, we supply material to each and every corner of the nation. We have various ranges of Products, which never leaves our Customer dissatisfied. The dynamic vision of management adds up to a win-win combination for our valued clients.

When you work with Bhagyoday Belt Company, you can be sure you will get the right solution for your needs. You can select the best quality, most appropriate product for your specific application.

We supply products of Bando, Contitech, Dongil, Fenner, Gates, Mega Dyne, OptiBelt, Mitsuboshi, Super Fine and Dunlop.

To provide the Indian Market with a premium quality product, outlasting our companies.

Customer satisfaction based on product and application knowledge and prompt servicing.

To Maintain & Continue the best service in the market.

Constant Growth along with our Suppliers and Customers by supplying the finest quality product in the Belting Industries for every Industrial Application.

-

Posted: June 23, 2017|Read more »

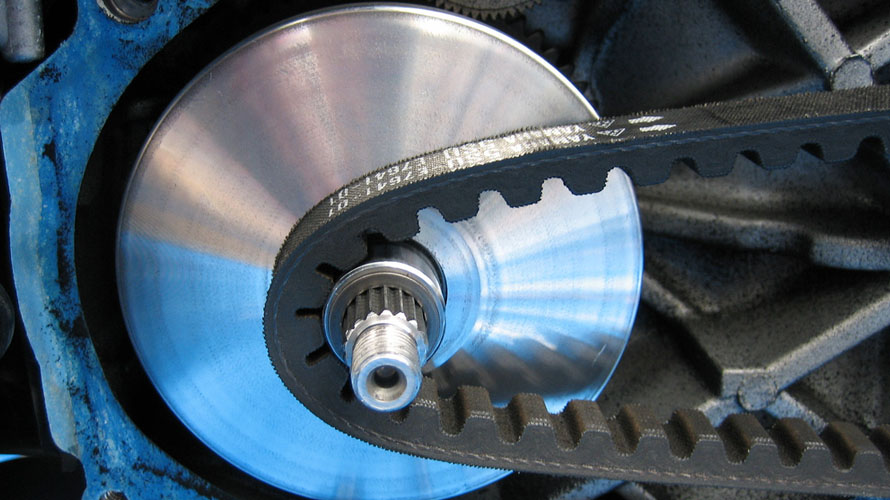

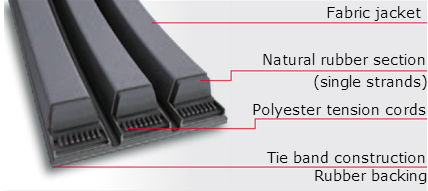

A belt consisting or two or more strands joined together is a banded belt. The two or more v-belts are vulcanized together with a tie band that makes it a homogeneous belt.

The size of the individual strands is the same as a single v-belt so it can operate on regular sheaves, meaning that a sheave with two or more lines can be used with a banded belt or several single belts, with no difference on size and adjustment, although a banded sheave is recommended to be used with banded belts only, due to the homogeneous tension applied to all the strands of the belt.

Why a banded belt

Most drives can work fine with several single belts installed, however, there are some cases on which the belts can come off the sheave or turn over. These cases are caused by pulsating or shocking loads. Several engines and systems with driveR and driveN types have periodic load variations, which cause changes on belt tension along the drive. If the tension changes are greater than the natural damping and the frequency of these fluctuations is synchronized with the natural frequency of the vibration, the amplitude is high enough to be considered.

If the vibration is vertical, it has no implication to the alignment of the shaft or belts function, but most of the times, the vibration has an horizontal component, which will force the belt to enter the sheave misaligned.

It is here when the belt can turn over or go off the sheave, and a way to prevent this lateral vibration is by making the belt more stiff or rigid in the side to side direction. Banded belts are harder to turn or be thrown off the sheave because they are more rigid and each strand is working at the same tension as the other ones.

-

Posted: June 23, 2017|Read more »

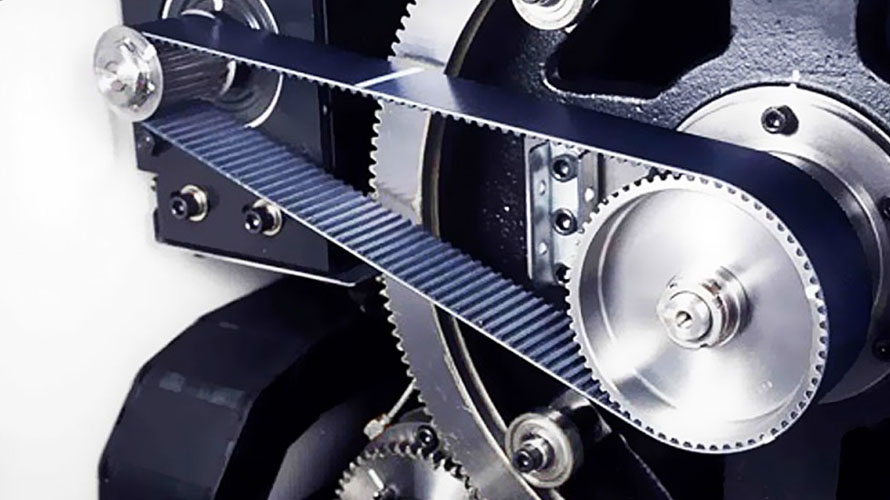

One of the mayor advantages that V belt systems has is that they are one of the most silent, effective and long lasting transmission systems while at the same time are one of the ones that requires the least maintenance.

A proper inspection during the service will ensure the efficiency of the system. In other blogs we have mentioned the impact that alignment and tension among other factors may have on a V Belt system but we have talk very little about the condition of the Sheave grooves and how we can determine if we have a problem there that needs our attention.