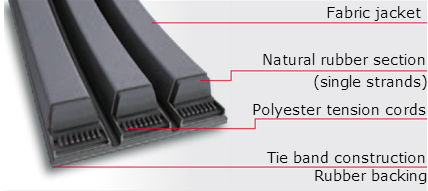

A belt consisting or two or more strands joined together is a banded belt. The two or more v-belts are vulcanized together with a tie band that makes it a homogeneous belt.

The size of the individual strands is the same as a single v-belt so it can operate on regular sheaves, meaning that a sheave with two or more lines can be used with a banded belt or several single belts, with no difference on size and adjustment, although a banded sheave is recommended to be used with banded belts only, due to the homogeneous tension applied to all the strands of the belt.

Why a banded belt

Most drives can work fine with several single belts installed, however, there are some cases on which the belts can come off the sheave or turn over. These cases are caused by pulsating or shocking loads. Several engines and systems with driveR and driveN types have periodic load variations, which cause changes on belt tension along the drive. If the tension changes are greater than the natural damping and the frequency of these fluctuations is synchronized with the natural frequency of the vibration, the amplitude is high enough to be considered.

If the vibration is vertical, it has no implication to the alignment of the shaft or belts function, but most of the times, the vibration has an horizontal component, which will force the belt to enter the sheave misaligned.

It is here when the belt can turn over or go off the sheave, and a way to prevent this lateral vibration is by making the belt more stiff or rigid in the side to side direction. Banded belts are harder to turn or be thrown off the sheave because they are more rigid and each strand is working at the same tension as the other ones.